Reliable weight tracking for better decisions

Automated monitoring of sow body condition – for better feed efficiency, higher productivity, and healthier litters

Data that make a difference

Automatic body condition monitoring

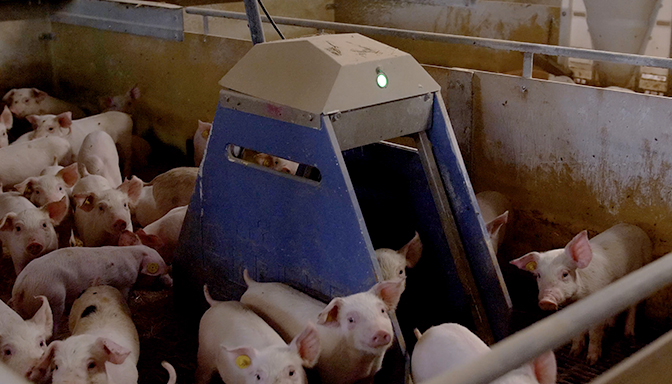

FREEDA Sow Monitor gives you accurate insight into sow weight development during gestation – completely without extra handling or stress.

The system records weight automatically as the sows move through the ESF station and presents an average of the most recent measurements. This provides a realistic and stable picture of each sow’s body condition and progress.

By basing feeding on real data, you avoid both over- and underfeeding, save feed, and ensure optimal conditions for both sow and piglets.

Automated weighing – without stress

Sow Monitor integrates directly with FREEDA Dynamic ESF or can be connected to Walk Through.

As the sows naturally pass the scale after feeding, the system automatically records their weight.

No stops, no manual handling – just continuous, stress-free data collection.

From visual assessment to data-driven feeding

Weight can vary by more than 35 kg among sows with similar backfat thickness at insemination.

That difference can mean up to 0.45 kg variation in daily feed requirements – adding up to around 20% difference in total feed allocation and roughly 45 kg variation over the gestation period.

Sow Monitor removes that uncertainty by providing a documented basis for accurate feed distribution.

The result is optimal body condition, faster reproduction, and more uniform litters.

Optimise your feeding strategy – automatically

The overall goal of accurate feeding during gestation is to develop a sow with the right body condition – one that provides optimal nourishment for her new litter and is physically ready for farrowing and subsequent milk production.

Several studies have shown that even in well-managed gestation units, one in three sows does not have the ideal condition when moving to farrowing.

With continuous and reliable weight data, feed levels can be adjusted precisely to each sow’s individual needs.

This means fewer days of feed waste, lower overall feed consumption, and better preparation for farrowing – both economically and genetically.

Ready to gain full control of your sows?

Combine your ESF solution with Heat Detection for complete insight into sow status, and with Location Feeding for a full feeding history throughout the entire production cycle.

FREEDA Gilt Training ensures optimal adaptation to ESF feeding.

FREEDA Heat Detection

Click to see more...

FREEDA Location Feeding

Click to see more...

FREEDA Gilt Training

Click to see more...

FREEDA Solutions – familiar solutions under a new name

FREEDA carries on the legacy of Nedap Pig Solutions – same products, same quality, same reliability. With a focus on innovation and long-term development, we build on this strong tradition and deliver future-proof solutions to pig producers worldwide.

Benefits of FREEDA Sow Monitor

Minimises errors from visual assessment and backfat measurement

Supports correct feed levels and uniform piglets

Stress-free, automatic data collection with no extra handling

Frees up time for other tasks in the barn

Integrates seamlessly with Walk Through and Dynamic ESF

Proven in practice

Facts gain strength through experience. Discover how producers around the world use our solutions to achieve documented results in their barns.

“After installing the FREEDA Walk-In system, the herd is calmer and more uniform – and the feed savings speak for themselves.”

“AutoPig® is an essential tool for maximising growth and optimising feed efficiency.”

Your reality is our starting point

At Agrisys, the solution starts with you.

Select the animal group that is relevant to you – and get a comprehensive overview of systems that create value in your specific production.

Sows and Gilts

Find the optimal solutions here

Weaners and Finishers

Find the optimal solutions here

Breeding

Find the optimal solutions here

More than technology – experience that makes a difference in everyday life

At Agrisys, we don't just work with equipment – we work with your reality.

We have many years of experience in developing solutions for modern pig production, and we know the demands you face:

Efficiency, animal welfare and financial results – every day.

That is why we deliver well-thought-out systems and solutions that work in practice.

From automated feeding, weighing and bedding to data you can actually use.

Whether you run a single herd or an integrated production, you get access to specialised knowledge, reliable technology and support

that accompanies you every step of the way.

News from Agrisys

Stay up to date with the latest news and insights from Agrisys. Here, we regularly share relevant tips, inspiration, and stories focused on animal welfare, innovation, and efficiency in pig production.

Explore our blog posts and news updates below – created to support you and your operation in your daily work, helping you stay ahead with the best solutions and industry trends.

FREEDA bygger fremtiden på Nedaps arv

AutoPig® – når data bliver til bedre beslutninger