Focus on weaners and finishers

Find solutions that match your daily needs – from feeding strategy and weighing to sorting, data, and reliable automation

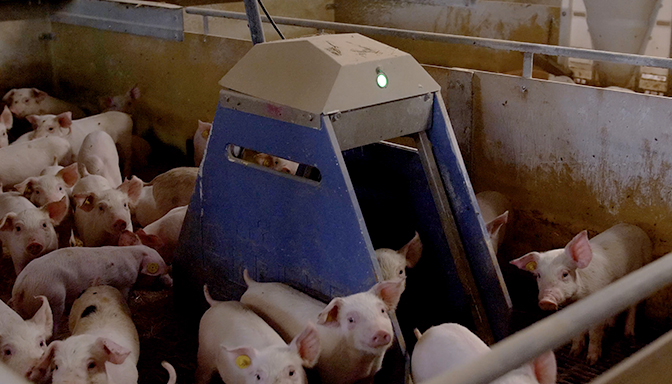

When small pigs grow into strong results

From weaning to slaughter delivery, you need solutions that ensure a stable start, optimal growth, and precise control of feeding and flow.

Here you’ll find an overview of all our systems and technologies developed specifically for these production phases – with a focus on animal welfare, efficiency, and results.

Control System

Take control with a single overview. Our control system connects feeding, weighing and results so you can document, analyse and act, wherever you are.

AutoPig®

Gain insight into growth and feed utilisation in real time. AutoPig® continuously records weight, allowing you to optimise feed changes and monitor herd performance – simply and accurately.

Sorting

Create uniform groups with automatic weighing and sorting. FREEDA Sorting ensures precise control of slaughter weight and feeding, so you can deliver at the right time.

PPT

Get a complete overview of feed efficiency and growth. FREEDA PPT makes it possible to test feed and genetics in practice, allowing you to document results and optimise through data and knowledge.

AirSys Bedding

Our Welfare system automatically distributes bedding and rooting material, meets all requirements, and saves time – intelligent, documented, and fully adapted to your barn.

GateSystem

Minimise infection risk with externally placed gate systems. Feed is received outside the farm and automatically transferred in a closed flow to the silo or kitchen – with no physical access to the barn.

AirSys Feed system

Deliver feed precisely and hygienically with air pressure. AirSys comes in several versions – from simple feed transport to complete solutions with MultiPhase and optional wet feeding at the outlet.

ChainSys Feed system

Move feed safely and efficiently – even in large volumes. ChainSys provides reliable transport to barn sections or the feed kitchen, tailored to capacity and biosecurity requirements.

BatchSys Feed system

Precise feeding with full flexibility. BatchSys builds on ChainSys and delivers portions on demand – ideal for multiple mixes, phases, and strategies within the same system.

MultiPhase Feed system

Full flexibility and high feeding precision. MultiPhase builds on AirSys and enables smooth feed changes and targeted adjustment in every growth phase.

From weaning to finishing weight

Managing a production with weaners and finishers is about combining rapid adaptation, precise feeding, and a reliable flow towards the right slaughter weight.

Each phase comes with its own challenges – from growth and feed transition to delivering a uniform group at the optimal time.

With our dependable solutions, you gain a strong foundation for ensuring steady growth and delivering animals of the right quality and within target weight – every time.

More than technology – experience that makes a difference in everyday life

At Agrisys, we don't just work with equipment – we work with your reality.

We have many years of experience in developing solutions for modern pig production, and we know the demands you face:

Efficiency, animal welfare and financial results – every day.

That is why we deliver well-thought-out systems and solutions that work in practice.

From automated feeding, weighing and bedding to data you can actually use.

Whether you run a single herd or an integrated production, you get access to specialised knowledge, reliable technology and support

that accompanies you every step of the way.

News from Agrisys

Stay up to date with the latest news and insights from Agrisys. Here, we regularly share relevant tips, inspiration, and stories focused on animal welfare, innovation, and efficiency in pig production.

Explore our blog posts and news updates below – created to support you and your operation in your daily work, helping you stay ahead with the best solutions and industry trends.

FREEDA bygger fremtiden på Nedaps arv

AutoPig® – når data bliver til bedre beslutninger